| Sign In | Join Free | My entremaqueros.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My entremaqueros.com |

|

Brand Name : KEYE

Model Number : KVIS-B

Certification : NO

Place of Origin : China

MOQ : 1 SET

Price : Negotiable

Payment Terms : L/C, T/T

Delivery Time : 4 to 6 weeks

Packaging Details : Fumigation-free wood

Supply Ability : 1 set per 4 weeks

Item : Visual Inspection Machine for Bottles

Colour : OEM

Inspection types : Bottles

Applicable : Quality inspection

Structure : Stable

Core technology : AI Inspection

MOQ : 1 set

Package : Wood packing

Market background

With the improvement of living standards and economic development, the demand for beverages in the beverage market is also increasing sharply, and product quality is increasingly concerned by consumers. The appearance defects of plastic bottles directly affect the consumer experience. In order to reduce the outflow of defective products, enterprises need to increase the inspection process. The increase of quality inspection personnel also brings high labor costs, followed by management costs. Now, the intelligent defect detection system for beverage bottles provides a scientific solution to these problems.

The plastic bottle visual inspection machine can quickly and efficiently identify various appearance defects in the bottle body, replace manual work, and automatically remove defective products. With bottle blowing machine, cap sorting machine, etc., it can realize the systematization from material sorting, detection to packaging Services can be widely used in dairy products, emulsification, beverages, cosmetics, medicine and other industries, with high investment value.

Detection procedure

| a.)Detection of the bottom of the outside of the bottle (1 set of camera): detect whether there are holes, black spots, stains and other defects. |

| b.)Detection of the bottom of the inside of the bottle (1 set of camera): detect whether there are black spots, stains, foreign objects and other defects. |

| c.)Bottle mouth detection (1 set of camera): detect whether there are deformation, lack of material, overlap, burrs, black spots, stains, and other defects, to ensure that the bottle mouth is intact. |

| d.)Bottle body detection (8 sets of camera): inspect all appearances for defects such as black spots, stains, impurities and damage, holes, and serious uneven thickness. |

| e.)Detection speed: 200-220 pcs/min |

| f.)Detection accuracy: 0.2mm |

| g.)Precision: 99% |

| h.)Detection range: Appearance of the entire bottle |

System configurations

| Name | Quantity | Unit |

| Motor | 4 | pcs |

| Coupling | 4 | pcs |

| Bearing seat | 8 | pcs |

| Belt | 4 | pcs |

| Transmission Parts | 1 | set |

| Frame | 1 | set |

| Rocker | 1 | set |

| Whirlpool pump | 1 | set |

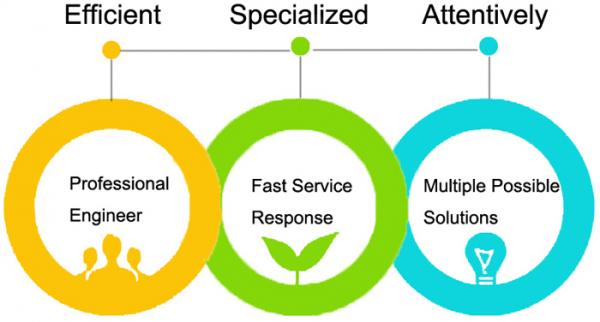

After-sale service

The company has a complete technical service team and rapid response mechanism, and has dedicated service specialists for each customer, who can receive technical consultation and fault reports from customers at any time. And to ensure rapid response to customer emergencies, to ensure that customers receive satisfactory service.During the epidemic or due to special reasons, when after-sales engineers are unable to reach the site, the service center can remotely adjust customer equipment for troubleshooting and technical consultation.

After the equipment arrives at the customer site, the after-sales engineer arrives in time to carry out equipment installation, commissioning, and operation training. The product quality of the whole machine is traceable, and the quality warranty period is 1 year from the date of acceptance. In the event of non-human faults during the warranty period, after-sales engineers will quickly arrive at the site or provide remote guidance for free maintenance.

|

|

Visual Inspection Machine for 500ml Bottles and Plastic Packaging Container Images |